Chocolate Moulding Plant - FOR SOLID BARS, AND CHOCOLATE PRALINE OR BAR SHELLS

Chocolate Moulding Plant - FOR SOLID BARS, AND CHOCOLATE PRALINE OR BAR SHELLS

Contact us for price

Description

This Moulding Plant is a semi-automatic line, currently configured to produce a variety of products, including solid chocolate bars with/without inclusions, praline shells, filled pralines, etc.

Manual placement of the Moulds onto the Mould Infeed conveyor with Warmer, and the moulds then pass to a KNOBEL Depositor, this is used for all the chocolate and centre filling and depositing.

In this line one of the main products was a Solid Chocolate Bar with or without inclusions of nuts/seeds/peel, etc.

For the Inclusions and toppings in the bars, you use the BAT MACHINENBOUW Feeder & Weigher to take the dry ingredients and distribute them over the chocolate, after the Knobel depositor. The bar would then be cooled in the Hacos Tunnel.

To produce Praline Shells, you would place a Chocolate Wheel Machine or automatic chocolate tempering machine, which is not included in the HACOS HML-600S Line which would then turn over the mould after filling to produce the outer shell. This outer shell is then cooled in the Hacos Tunnel, and once cooled you would then run these moulds with cooled outer shell through the HACOS Line again, and using the KNOBEL can then fill the shell with a praline filling.

They would then need to be cooled again through the Hacos Tunnel.

After Cooling again, the Backing-off of the product (with chocolate) would be after a Flood Fill from the KNOBEL (or maybe an additional Chocolate Wheel/Mould Filling Machine can be inserted in-line with the Hacos, which is not included).

The HACOS Cooling Tunnel is used to cool ALL the products made on this line.

Products are manually demoulded. No Moulds included.

Item # 9134 – CHOCOLATE MOULDING PLANT

FOR SOLID BARS, AND CHOCOLATE PRALINE OR BAR SHELLS

Line can produce solid bars with optional nuts/nibs/seeds/candied peel, and chocolate shells for pralines

All currently set up as a complete running plant,

Manufactured by HACOS / KNOBEL / BAT MACHINENBOUW / SOLLICH

suitable for Mould sizes 275 x 175 x 25mms and 275 x 135 x 25mms

Speed of the moulds 7 or 8 moulds/minute (for bars of +/- 100 gram)

With SIMAR Vacuum Filling System including vacuum pump, to fill Tanks with either milk or dark chocolate buttons to melt

Two (2) 1800Kgs capacity Stainless Steel Jacketed Chocolate Tanks each with stirrers & motors & separate controls

One Chocolate Pump to use between both Tanks, plus pipework

Start of line with

approx.5metres long Mould Infeed Conveyor with Heatstrip Mould Warmer

SOLLICH 200FD Chocolate Temperer, 380Volts, 50Hz, 3Phase, 4.2kW

KNOBEL CCM-9 Chocolate Depositor for bars/shells or fillings, with agitator in hopper for the chocolate

Then through a BAT MACHINENBOUW Bucket Elevator Feeding Conveyor, feeding nuts/seeds/peel, etc. into a

10-Head Multi-Head Weigher that then weighs product to be spread & dropped on top of newly deposited chocolate into mould, with minimum weight being 2grammes of product onto the mould

Through a Vibratory Conveyor, and with 90Degree Pusher

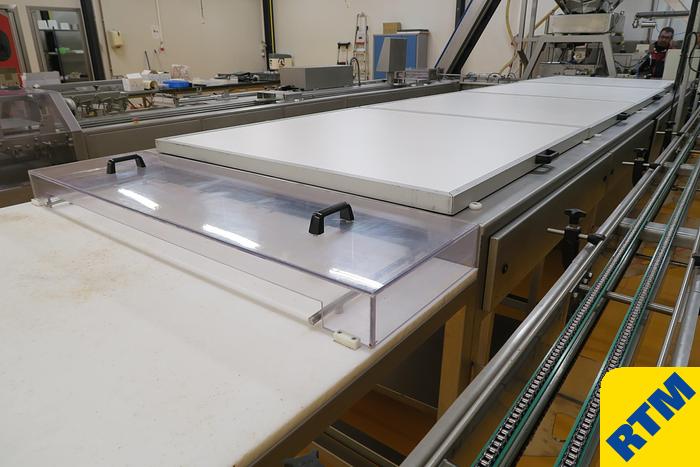

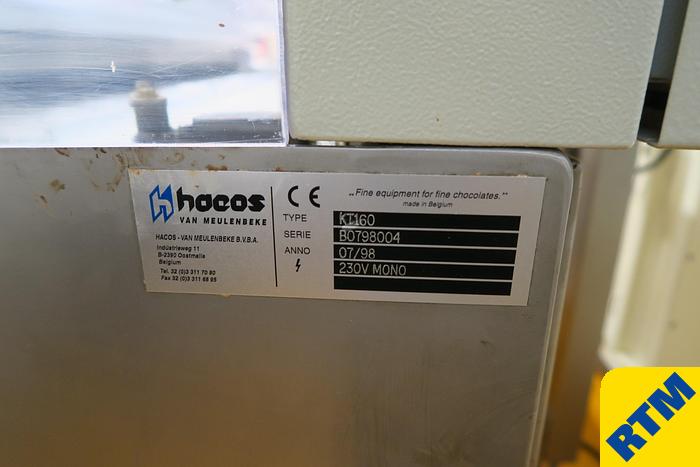

Then into a HACOS KT160 Cooling Tunnel, 4 x Moulds Across, Cold Air Cooling with compressor & condenser, 5metres long Cooling

Exit from Cooling Tunnel,

Manual Demoulding of product and placing of moulds back onto Mould Infeed Conveyor

For the Shell Forming, there is also a

HACOS HML-600S Line, running on 275 x 135 moulds, including Mould Warmer, Scrapers, Vibration, Fill Area, 180Degree Conveyor, Mould Turnover, Vibration, 2 x Bottom Scrapers, then manual mould turnover to then feed into

HACOS KT160 Cooling Tunnel.

Specifications

| Manufacturer | Hacos / Knobel / Sollich |

| Condition | Used |

| Stock Number | 9134 |